CUSTOMIZED SERVICE

CUSTOMIZED SERVICE

Saving the cost for your carbide tools

OED has produced 3000+ special tools for our customers over the 25 years. From the simple plates to precise tools, we always help our customer to make the qualified products.

Based on our skilled engineers, we can provide various carbide grades for our customers to suit their applications.

The grades from K01-K50, G10 to G60, and special requirements such as non-magnetic and wear-resistance grade for the medical, food industries. The suitable grade can make your tools more efficient.

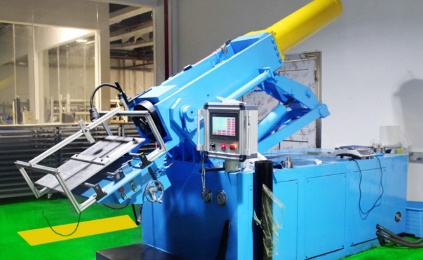

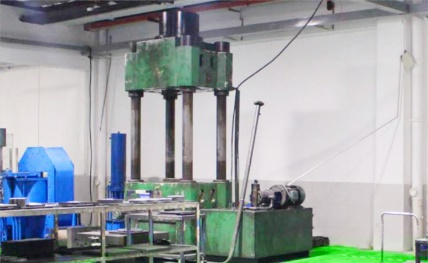

General equipment for making the carbide blanks:

The excellent production team helps us to produce the products as per the drawings in economy way.

Our production team is always looking for the best way for production to save the cost. For the complicated shapes and finished machined tools, our engineers will discuss and design the viable method. Even for a small quantity special tool, we can also provide good solutions for you.

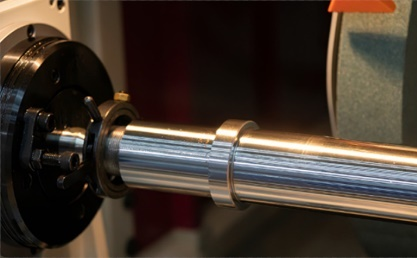

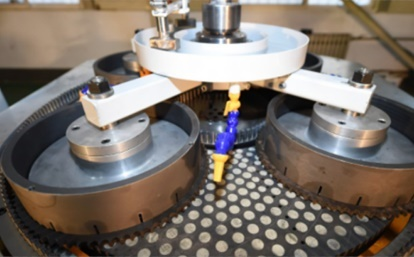

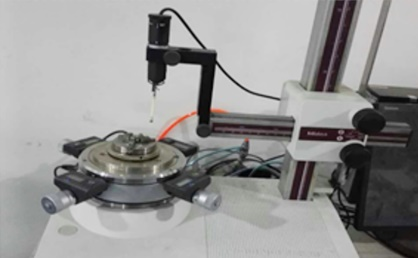

General machines for making the finished ground products:

Inspection is the important process for ensuring the quality as per the customer’s requirements.

For the raw materials inspection, such as Hardness, T.R.S, density, metallographic and other parameters.

For the dimension’s inspection, the geographic dimensions will be inspected according to the drawings.