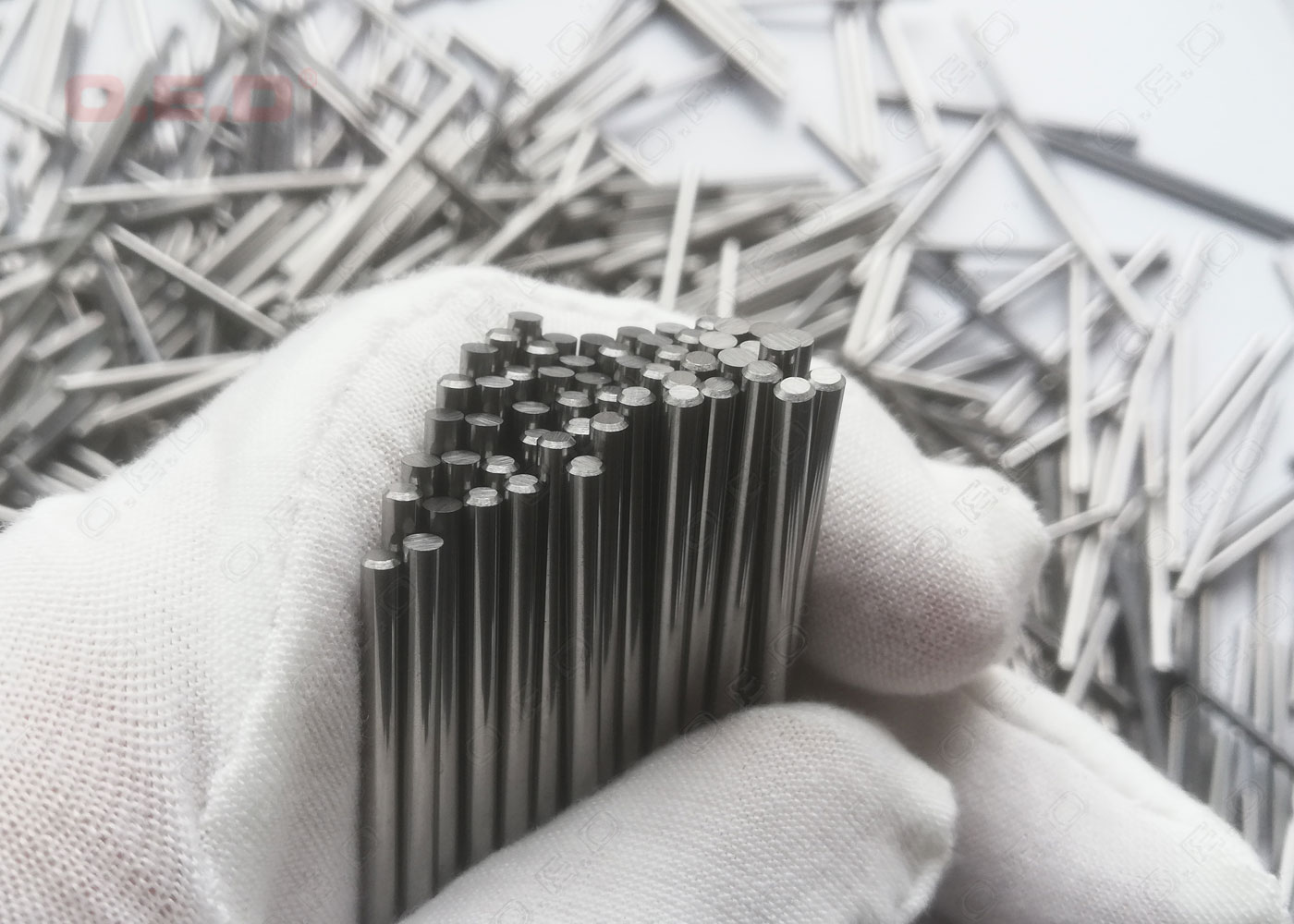

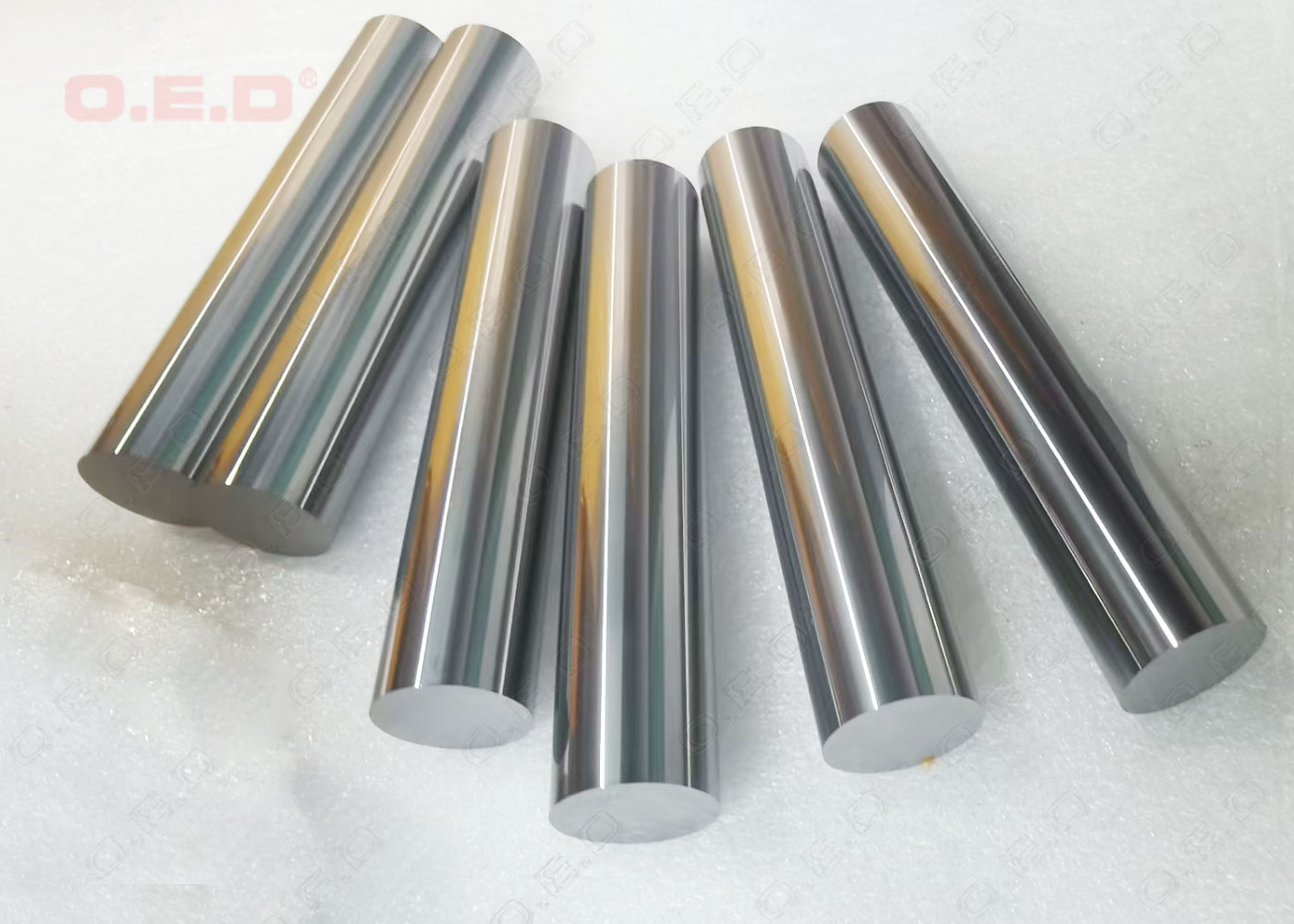

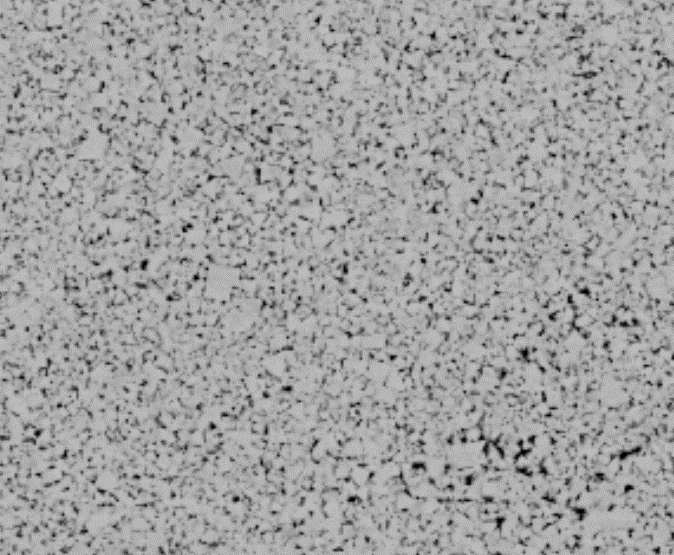

Carbide rodsCarbide rodsCarbide rod is the regular standard product of OED company. We have been manufacturing the high-quality carbide rods in the last 25 years. We tightly control each production process, ensuring the high quality of each batch. Almost all unground rods in grade OR40F (10% Cobalt with fine grain size) are in stock. All the raw materials of the carbide rods we produce are made by spray granulation tower, and they are pressed and dried in the same workshops with constant temperature and humidity, making sure 100% qualified raw materials into the sintered procedure. The inner structure of our carbide rods is optimized by using HIP sintering furnace and cryogenic treatment. Our cut-to-length rods and fine grinding rods are also the feature products due to the advanced grinding equipment we have. The roundness and straightness of our grinding rods can be within 0.005 and the roughness can be as low as Ra0.05. About Grades: OED keep developing the new grades for different applications. The new grade OR35N(9% Cobalt as binder) with Nano grain size 0.2μm, T.R.S. can up to 5000 N/mm2. The hardness can up to HV30 1950. Brief introduction of OR35N:

Brief introduction of OR40F: Other grades include K01 to K60 are all available. Please kindly the datasheet for checking. |